lanri activated carbon

Introduction to columnar activated carbon:

The columnar activated carbon of coal quality is processed by a series of production processes, and the appearance is amorphous particles.

Coal columnar activated carbon has developed pore structure, good adsorption performance, large surface area, light weight, strong adsorption

capacity, good wear resistance, high mechanical strength, long service life characteristics, It can adsorb benzene, toluene, ketones, alcohols,

tetrahydrofuran, dichloromethane, trichloromethane, trichloroethylene, perchloroethylene, carbon disulfide, formyl, gasoline, fluorocarbons and

other VOC organic waste gas.

Columnar activated carbon specifications:

Diameter: phi is 0.9 mm / 1.5 mm / 2 mm / 3 mm / 4 mm / 5 mm / 6 mm / 8 mm / 9 mm, can be customized

Packing: inner plastic 25kg/ bag, ton bag

Application scenario: Coal columnar activated carbon is widely used in waste gas purification, chemical raw material gas, chemical syngas, pharmaceutical industry gas, beverage carbon dioxide gas, hydrogen, nitrogen, hydrogen chloride, ethane gas purification, gas purification and separation, atomic facilities exhaust gas, etc. There are also impregnated coal columnar activated carbon, such as KOH activated carbon, NaOH activated carbon, sulfur leaching activated carbon, desulfurization and denitrification activated carbon, pickling activated carbon, etc., used to remove special harmful gases.

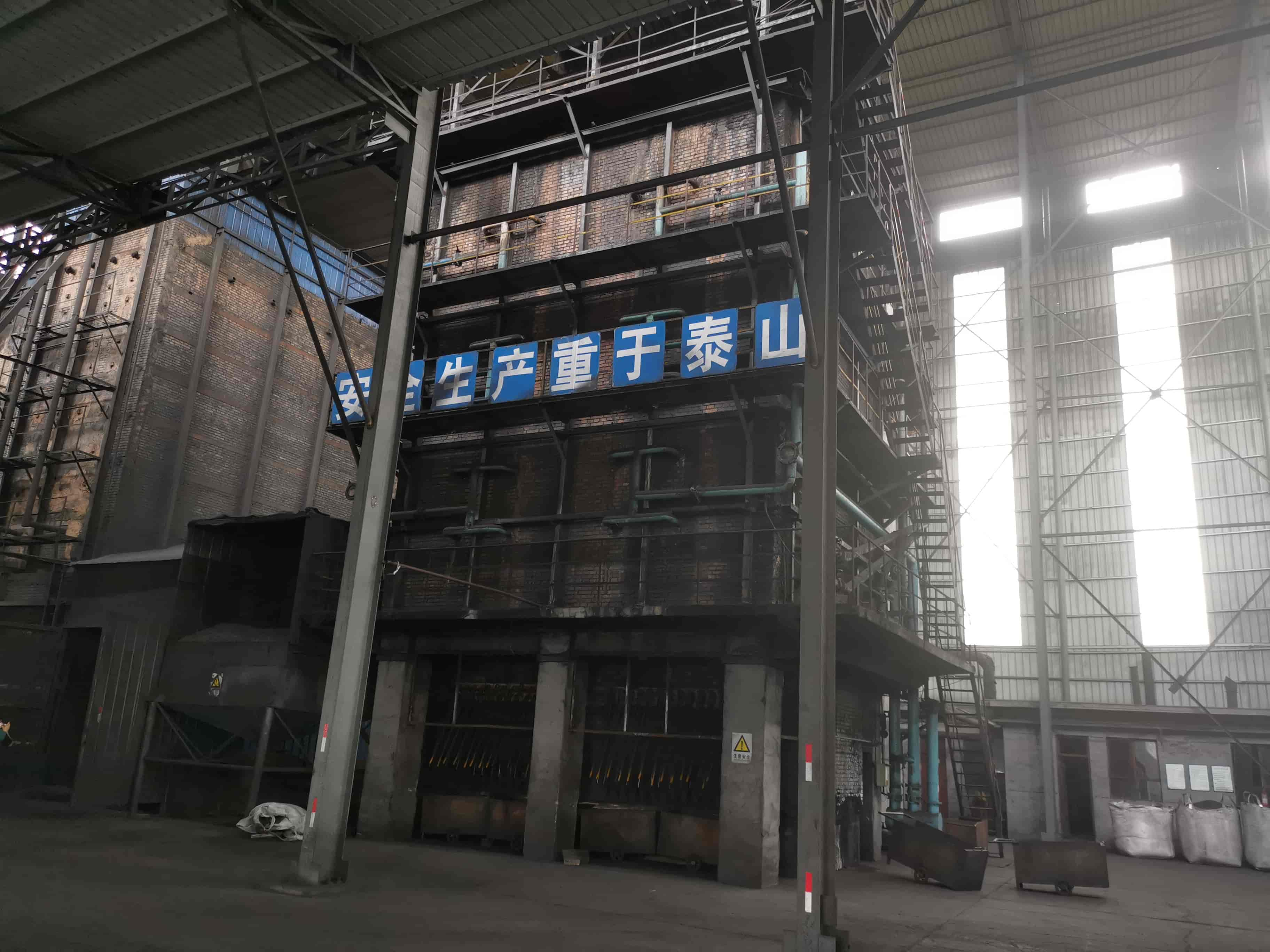

Production process of columnar activated carbon:

The production process of coal columnar activated carbon should first ground the raw coal to a certain fineness (generally more than 95% through 0.08

mm), add appropriate binder (commonly used coal tar) and water at a certain temperature kneading, extrusion into carbon strips; After the carbon strip

is dried, it is carbonized and activated as coal columnar activated carbon. Coal columnar activated carbon products sometimes need to be pickled,

impregnated, modified and other treatments according to market requirements, which have met customers' adsorption needs.

Columnar activated carbon characteristics:

Henan Blue day activated carbon has the advantages of developed void structure, large specific area, strong adsorption capacity, high mechanical strength, small bed resistance, good chemical stability, easy regeneration, durable and so on. Due to the reasonable pore size distribution of the product, it can achieve greater adsorption and desorption, thus greatly improving the service life of the product (2-3 years on average), which is 1.4 times that of ordinary coal carbon.

![]()